Product: C-Coil Bending- Cutting Machine for turbo rotor winding

Type: AT-CCCO-2

Edition: 12/15

download Product Specification C-Coil Bending- Cutting Machine AT-CCCO-2

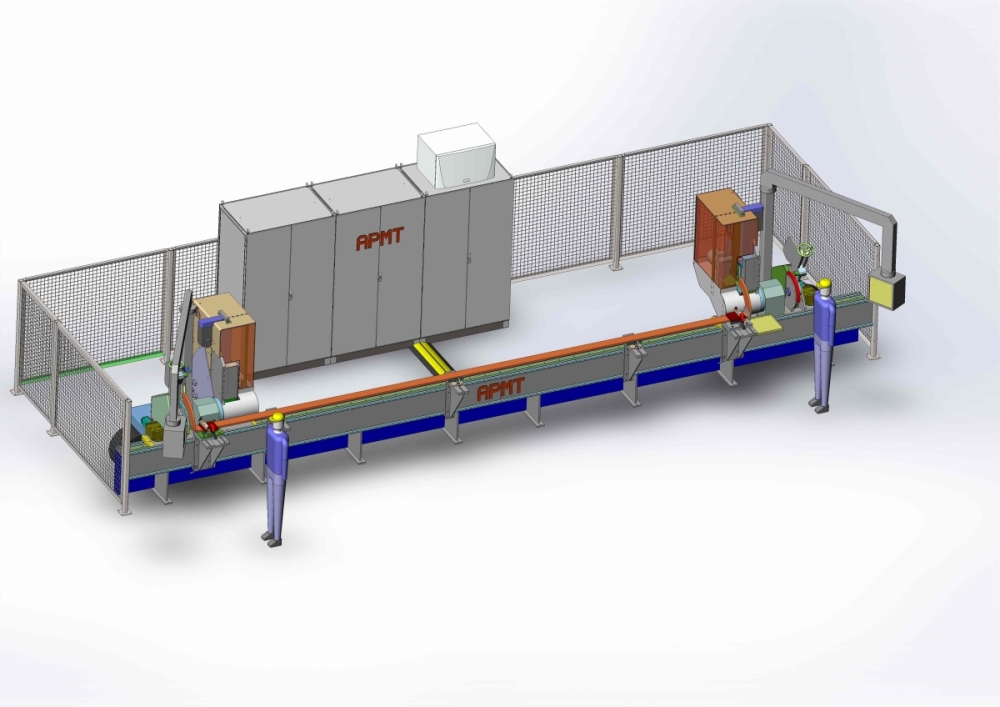

The C-Coil-Cut-Off machine is build for bending rotor C-Coils in radial direction and for cutting and milling the end surface of the C-Coil package to the required final shape. No reworking of the C-Coils is necessary. After the bending- cutting- and milling process, the C-Coil package can be inserted into the rotor slots of the generator shaft without any post-processing.

2. Technical Data

Machine length: approx. 10.100 mm

Machine width: approx. 3.600 mm

Machine height: approx. 2.600 mm

Machine weight: approx. 7.000 kg

Max. Coil length: 7.500 mm

Min. Coil length: 2.500 mm

Max. Coil width: 50 mm

Max. Coil height: depends on bending radius

Min. bending radius: 200 mm

Max. bending radius: 415 mm

Max. rotation angle machining station: 40° backwards, 70° forwards

Resultant range of suitable coil angels: 20° – 90°

3. Scope of supply

The machine consists of the following main components:

- Machine bed incl. guide rails

- 5 pc. clamping and adjusting consoles

- 2 pc. bending stations incl. radial guiding devices

- 2 pc. bending segments with required bending radius

- 2 pc. machining stations incl. cutting units, milling units and clamping devices

- 2 pc. machining segments with required coil radius

- 2 pc. operating panels and remote controls mounted on a swivel bracket.

- Electrical cabinet

- Hydraulic unit

- Cable carrier for guiding electrical and hydraulic wires and hoses

- Safety fence incl. safety doors for entrance

4. Process result